The 13th China CNC Machine Tool Show (CCMT2024) was grandly opened on 8 April 2024 at Shanghai New International Expo Centre, with the theme of “Focus – Digital – Connected – Smart Manufacturing”. With the theme of ‘Focus – Digital – Connected – Smart’, CCMT2024 will showcase the latest achievements of the machine tool industry in digitalization, interconnection, smart manufacturing and efficient machining, which also reflects that the global machine tool industry is marching towards a broader future with a firmer pace and a clearer direction. Shandong Youka CNC Machinery Co., Ltd. will elaborate the future development trend of CNC machine tools from CNC system, AI empowerment, 5-axis machine tools, and composite upgrading.

CNC system

The CNC system industry is an industry with high technical content and rapid technological development. To promote the overall development of the industry, it is necessary to do a good job in technical exchanges.

Main Exhibits of CNC System

At this exhibition, foreign companies exhibiting CNC systems mainly include Siemens, Fanuc, Mitsubishi Electric, Heidenhain, Mazak, etc. Chinese CNC companies mainly include HNC, GSK , SYNTEC, LYNUC, CASNC etc.

1.Siemens

With the theme of “Digital Drive, Achieving a Sustainable Future”, Siemens comprehensively showcased its CNC system products and digital solutions, including the new generation of “digital native” high-end CNC system SINUMERIK ONE, mid-range CNC system SINUMERIK828 and standard CNC system SINUMERIK 808.

2.Fanuc

FANUC exhibited the latest FANUC CNC—FANUC i0-F Plus STEP2 system, intelligent processing system FX FANOVI, and FANUC functional group solutions for emerging industries (lathes, multi-axis, medical, molds, new energy vehicles, 3C/5G, green machine tools, etc.).

3.Heidenhain

HEIDENHAIN presented the TNC7, a CNC control whose new version 18 software offers several enhancements, such as DCM collision monitoring, OCM pendulum milling, and MAS six-degree-of-freedom graphic-assisted setup functionality, to further improve process reliability and user-friendliness.

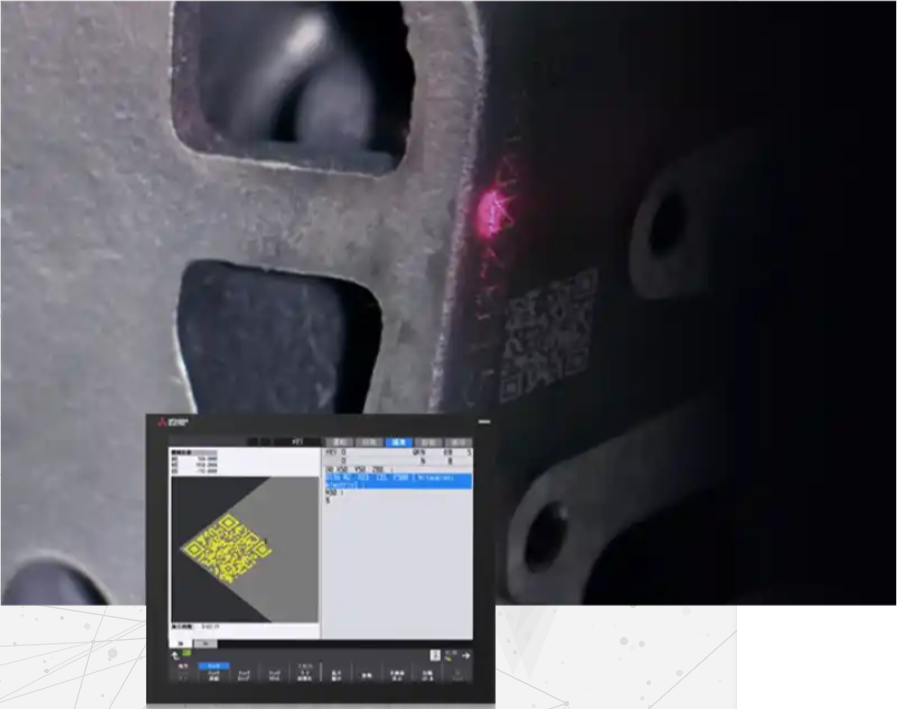

4.Mitsubishi

Mitsubishi Electric mainly launched and introduced the new M800V/M80V CNC device, which upgraded the software and hardware based on the original M800/M80, and added NC Machine Tool Optimizer, cutting load control, QR code processing cycle, 3D processing simulation and other technologies to the functional applications.

5.Mazak

Mazak showcased its new Smooth series CNC system MAZATROL Smooth AI, which is equipped with AI production efficiency improvement technology, advanced digital simulation functions, digital twin technology and advanced automation adaptability.

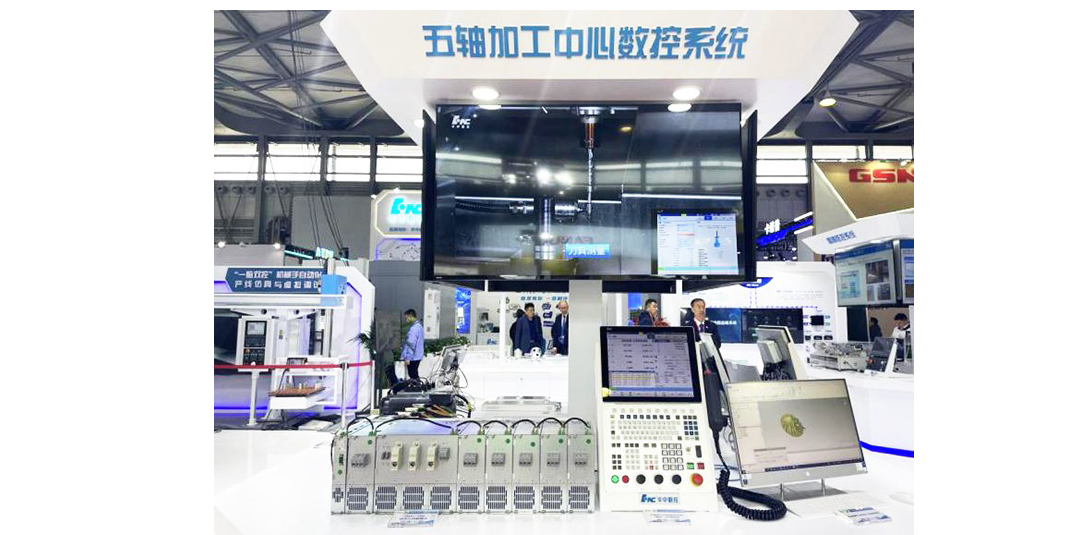

6.HNC

HNC takes ‘AI empowered five-axis leading composite upgrade’ as the theme of the exhibition, and brings ‘HNC 9-type intelligent CNC system, HNC 8-type high-grade five-axis CNC system, HNC 8-type milling and turning composite CNC system and other exhibits to appear. HNC 9-type leading intelligent CNC system, integrated AI chip, fusion of AI algorithms, convergence of big data, fusion of large models, integrated computing power, to build an intelligent ecological technology to provide support. HNC 8 high-end 5-axis CNC system product package consists of ‘hard set’ and ‘soft set’ two parts. The system breaks through the surface super smooth interpolation, feed speed adaptive, RTCP parameters fast automatic calibration, five-axis spatial error compensation, dynamic anti-collision and other technologies, so that the five-axis machining accuracy and machining efficiency is comparable to the international advanced level.

7.GSK

GSK exhibited the GSK 27i high-end multi-channel CNC system. GSK27i is a high-end intelligent CNC system for multi-axis and multi-channel complex processing applications. The functions and performance of the GSK27i CNC system are comparable to those of European high-end CNC system products. It targets the import substitution and industrial upgrading markets and is suitable for high-end five-axis machine tools, high-end machining centers, turning and milling, grinding, gear hobbing, gear grinding and complex processing equipment.

8.Syntec

SYNTEC has launched the latest featured products such as 22MA PLUS machining center controller, 22TBPLUS lathe controller, 7TA controller, disc motor, etc., and provided special functions and solutions such as automatic tool measuring special screen, servo tailstock special screen, DTRQ anti-collision, SYNTEC turning and milling composite CAD/CAM, etc.

9.LYNUC

Shanghai LYNUC exhibits CNC systems to support a variety of solutions: follower grinding, five-axis linkage, high-precision and high-speed screw direct-drive motion control, precision peripheral grinding applications, drilling and tapping machining centers, and other solutions, the main highlights of which are: drive and control based on the PWM transmission of an integrated servo controller, based on high-performance switching devices, servo amplifiers, high-performance direct-drive technology.

10.CASNC

Shenyang CASNC launched a full series of CNC system products, including high-grade, standard and special-purpose products. GJ610 supports a variety of types of five-axis machine tool structure, suitable for the machining of complex curved surface parts in space, such as engine magazines, blades, moulds, etc., and has high-grade functions such as RTCP control that supports participation of the third rotary axis and support for multi-axis coupling, inclined surface machining, five-axis manual feed, and spatial and circular interpolation that supports remote teaching. The machine is equipped with high-grade functions, such as feed axis commutation impact suppression, feed rate adaption under sudden change of cutting load, synchronous backlash elimination and other intelligent control technologies, which can satisfy the customer’s needs for a variety of high-grade machine tools.

AI artificial intelligence big model empowers CNC system

Through years of development, traditional CNC systems have solved many tasks with high determinism, and the problems that are difficult to solve are usually those with high uncertainty, whereas the methods of Artificial Intelligence (Big Data Intelligence, Big Models, etc.) can reduce the uncertainty of the tasks through the modelling of the associative relationships, and provide new ideas and methods for the current problems that are difficult to solve.

–Mitsubishi Electric has launched NC Machining AID, a machining diagnostic tool developed using Maisart, Mitsubishi Electric’s proprietary artificial intelligence technology, to analyse and diagnose machining data without the need for complex expertise.

–MAZATROL Smooth Ai from Mazak comes with AI productivity enhancement technology, advanced digital simulation capabilities, digital twin technology and advanced automation adaptability.

–HNC introduced AI consultation, machining code generation and process parameter optimisation of CNC system based on AI big model, which is highly practical.

–GSK also launched intelligent thermal compensation, intelligent anti-collision detection and other intelligent functions.

Popularization of 5-axis CNC machine tools

High-end five-axis CNC system, is the machine tool industry’s ‘strongest brain’, equivalent to the chip industry 7nm, 3nm process must be photolithography, equivalent to the engine of a large aircraft, is the necessary high-end manufacturing of cutting-edge heavy equipment. Moreover, five-axis CNC machine tools are better than three-axis machine tools in terms of machining accuracy, machining efficiency, consistency, stability, etc. Therefore, more and more customers, especially precision manufacturing customers prefer to choose five-axis CNC machine tools.

With the rapid development of China’s manufacturing industry, the five-axis CNC puts forward a strong demand for the future of five-axis high-end CNC machine tools will be more commonly used, which provides an excellent opportunity for China’s five-axis CNC machine tools, five-axis CNC system of leapfrog development.

At this exhibition, HNC newly launched high-end five-axis CNC system product package, breakthrough surface super uniform interpolation technology, intelligent feed-forward technology, high-speed high-precision high-response drive and motor technology, five-axis programming technology, fusion of five-axis machine tool machining process and big data intelligent analysis tools, to create programming – machining – measurement integration of the manufacturing of complex parts solutions, supporting high-performance five-axis machine tools, can be realised impeller, impeller, impeller disc, engine block cylinder head and other complex parts of high-precision and high-efficiency machining.

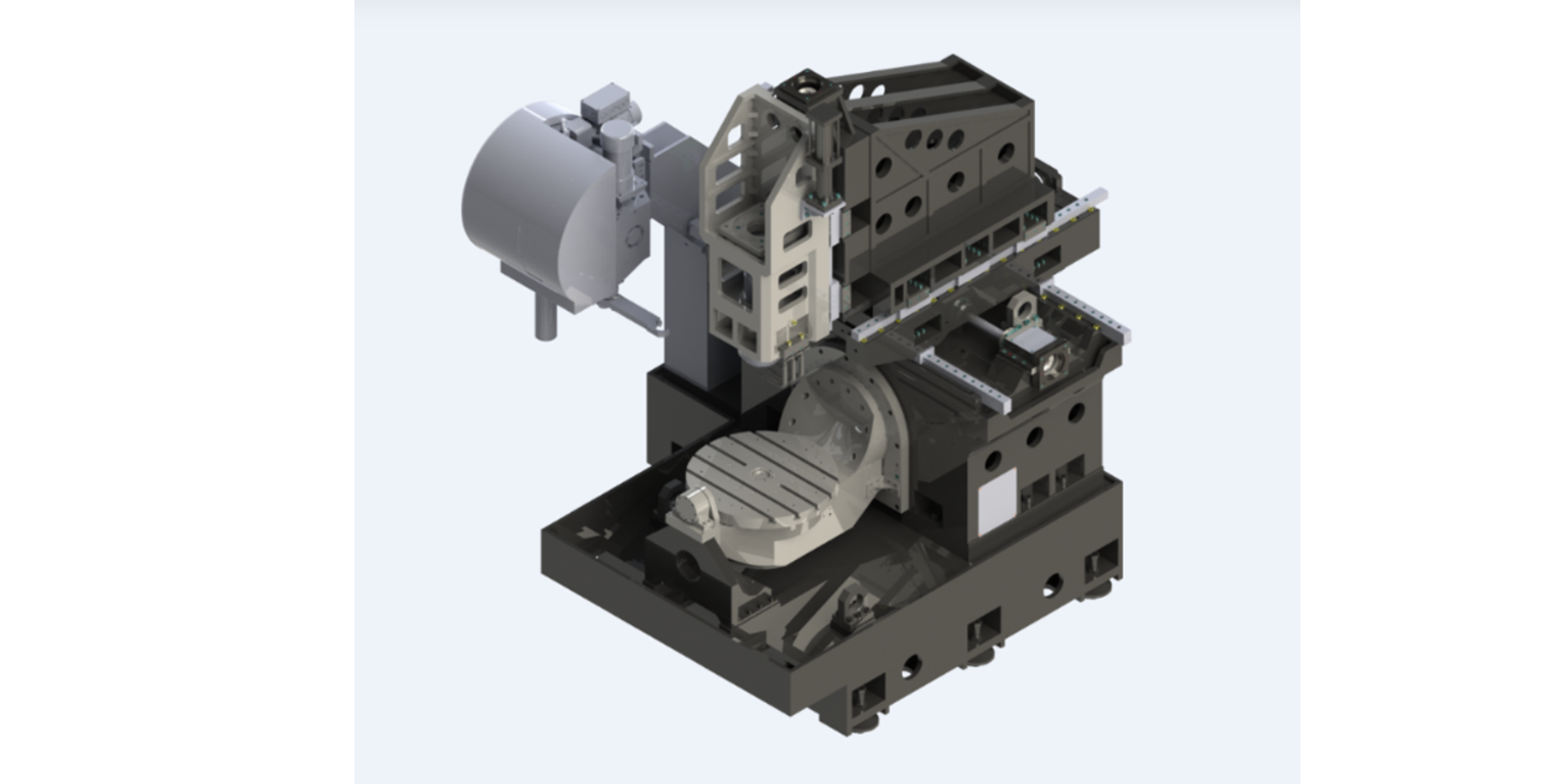

Composite CNC machine tools

With the increasing demand for machining efficiency, machining precision, cost reduction and efficiency, composite machining is increasingly being used in various fields.

A large number of composite processing machines are on display, including turning centres, 5-axis turning and milling composite, milling and turning composite, grinding composite and turning and milling composite. For example, HNC 8-type 5-axis turning and milling composite CNC system product package consists of CNC devices, high-performance drives, full-specification motors, CAM and process libraries, stand-alone automation, and rich software packages to create a new ecology of turning and milling composite.

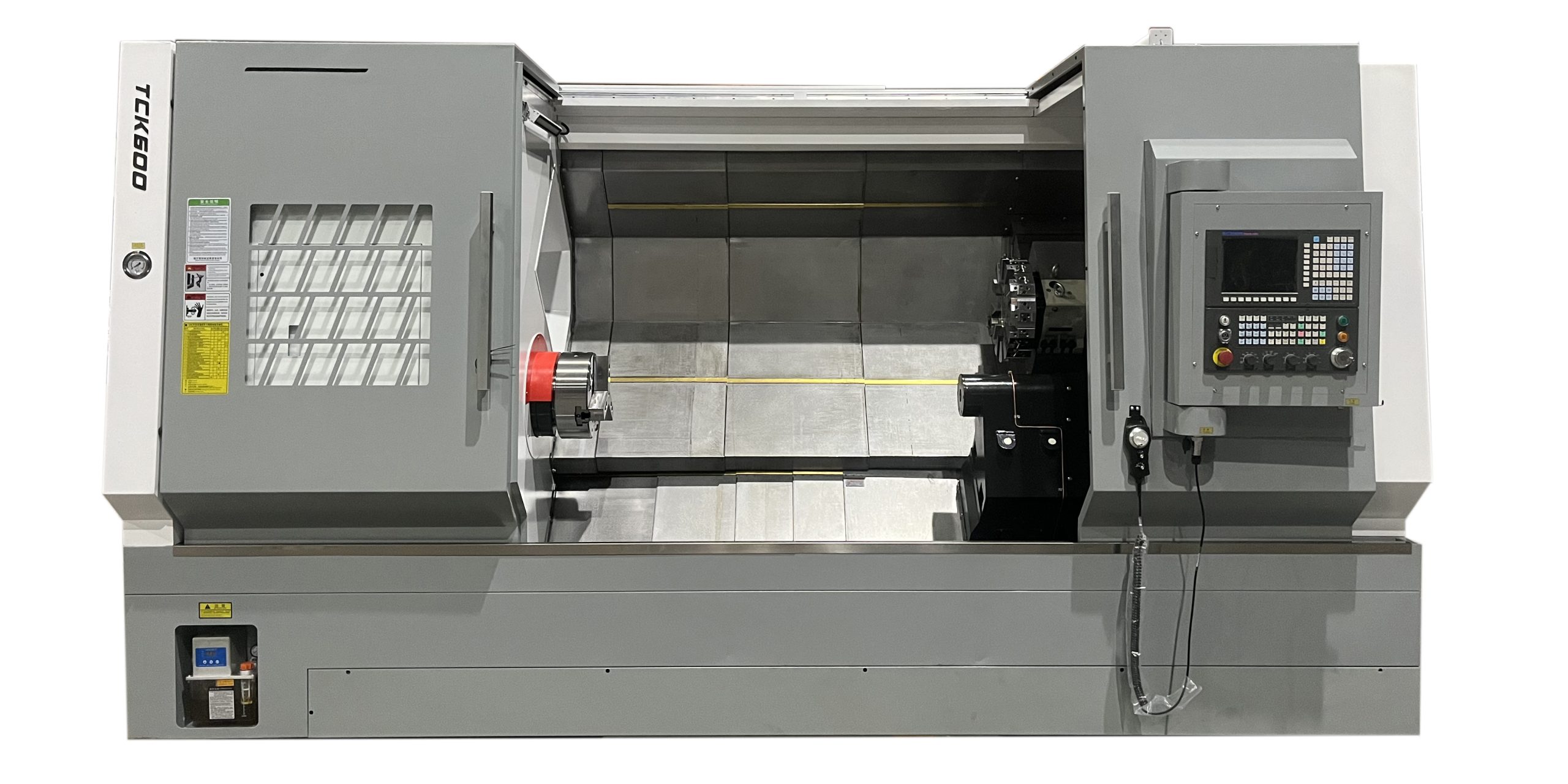

Chinese machine tools supporting CNC system statistics

After counting, the total number of Chinese CNC machine tools exhibited in this exhibition is 1006 sets.

-Classification by model

263 lathes, 120 mill-turn machines, 239 machining centres, 175 five-axis machines, 131 grinding machines, 62 gear machines and 17 other models.

-Classified by CNC system manufacturers

Foreign CNC systems mainly include Fanuc 296 sets, Siemens 172 sets, Mitsubishi 47 sets, Heidenhain 13 sets, Fagor 11 sets, other (NUM, Rexroth and other foreign brands 21 units), statistics supporting about 560 sets, accounting for about 55%.

Domestic CNC system mainly includes HNC CNC (136 sets ), GSK CNC (73 sets ), Syntec CNC (102 sets ), KND CNC (21 sets), KEDE CNC (10 sets), etc., a total of supporting about 446 sets, accounting for about 45%.

Compared with the statistics of CIMT2023 (foreign systems accounted for about 2/3, domestic systems accounted for 1/3), this exhibition of domestic CNC system supporting ratio to improve significantly, especially five-axis machine tools and other high-end machine tools configured with domestic systems accounted for a higher and higher proportion. For example, the exhibition of domestic five-axis CNC machine tools a total of 175 sets, including supporting HNC five-axis CNC system 38 sets, accounting for 22%, ranked second, second only to Siemens CNC system, a comprehensive illustration of China’s domestic system to replace the trend is becoming more and more obvious.

The future development trend of CNC machine tools

-Openness of the CNC system

With the rapid development of CNC technology, CNC systems are being transformed from specialised closed systems to flexible open CNC systems. Open CNC system is a revolutionary leap in the field of manufacturing technology, its hardware, software and bus specifications are open to the public, due to sufficient software and hardware resources can be used, the system hardware and software can be upgraded with the development of PC technology, not only to make the CNC system manufacturer and the user of the system integration to get a strong support, but also for the user’s secondary development is also convenient, and promotes the development and wide application of CNC system of multiple grades and varieties. Grades, varieties of development and wide application of CNC systems, both by upgrading or tailoring to form a variety of grades of CNC systems, but also through the expansion of CNC systems constitute different types of CNC machine tools, the development cycle is greatly reduced.

Siemens, Fanuc, HNC and other companies are providing developed CNC system technology platform for users to carry out secondary development, such as Huazhong 9-type CNC system as a depth of open platform for machine tool manufacturers, industry users and scientific research institutes to carry out intelligent research and application of the integrated development platform, classification of the APP independent integration, the formation of a series of self-developed APP, applied to many high-grade CNC machine tools.

-Digital twin technology empowers CNC

For machine tool users, there are problems of low design efficiency, high delivery cost and difficult monitoring process in machine tool design, delivery and operation. Facing the above pain points, it is necessary to carry out virtual design, simulation and debugging before the actual delivery and operation, and the operation process can also be monitored and feedback control, in order to improve the design and production efficiency and reduce production and processing costs. As an important intermediate link, the CNC system can well connect the upstream and downstream, and the 3D design, motion simulation, cutting simulation, PLC debugging, G-code debugging, collision avoidance, real-time monitoring and other functions are centrally embodied in the digital twin in order to achieve higher productivity and lower production costs, which is undoubtedly one of the important development trends.

-AI Artificial Intelligence Enabled CNC

The AI artificial intelligence approach also features self-learning, which learns from the problems captured in the CNC sensing, decision-making and control process, making the control system evolve to adapt to the actual task requirements in the scenarios of quality enhancement, process optimisation, health assurance and production management. Therefore, AI big model empowered CNC system will be one of the important trends.

-High speed, high accuracy of CNC machine tools

Small specification and light cutting machine tools will be towards the direction of high-speed high-precision development, moving table five-axis machine tools and bridge type five-axis machine tools will be more rapid development. With the aerospace field and some new industries such as the development of new energy automobile industry, the demand for such machine tools will be more and more.

-Complexity of CNC machine tools

Composite function can greatly eliminate the bulk of the process of processing in the transport, clamping and waiting time, the workpiece on the machine tool only once clamping positioning, both to reduce the processing of auxiliary time, but also improve the machining accuracy of the workpiece, so that the machining cycle is greatly shortened and reduce the number of work in progress in the processing plant. Composite machining is an important technical development direction for future CNC machine tools.

As a new generation of CNC lathe machine and vertical machining centers manufacturer in China, Shandong YOUKA CNC Machinery Co., Ltd. will follow the pace of CNC technology update, constantly update the advanced CNC system, improve the cutting accuracy of the machine and optimise the manufacturing process, in order to meet the different machining needs, and better serve the global customers.