Machining centers, with their high precision, high efficiency and multifunctionality, have become the preferred equipment for many manufacturing companies pursuing efficiency and quality. However, since there are different types of machining centers on the market, it may be difficult for people who do not understand these different types to choose the right machine. As a new generation manufacturing factory in China, YOUKA-CNC will introduce the classification of machining centers and their application areas in detail to help everyone better choose and use machining center equipment. The following content is YOUKA-CNC’s introduction to the classification of machining centers.

1.According to the machine tool form

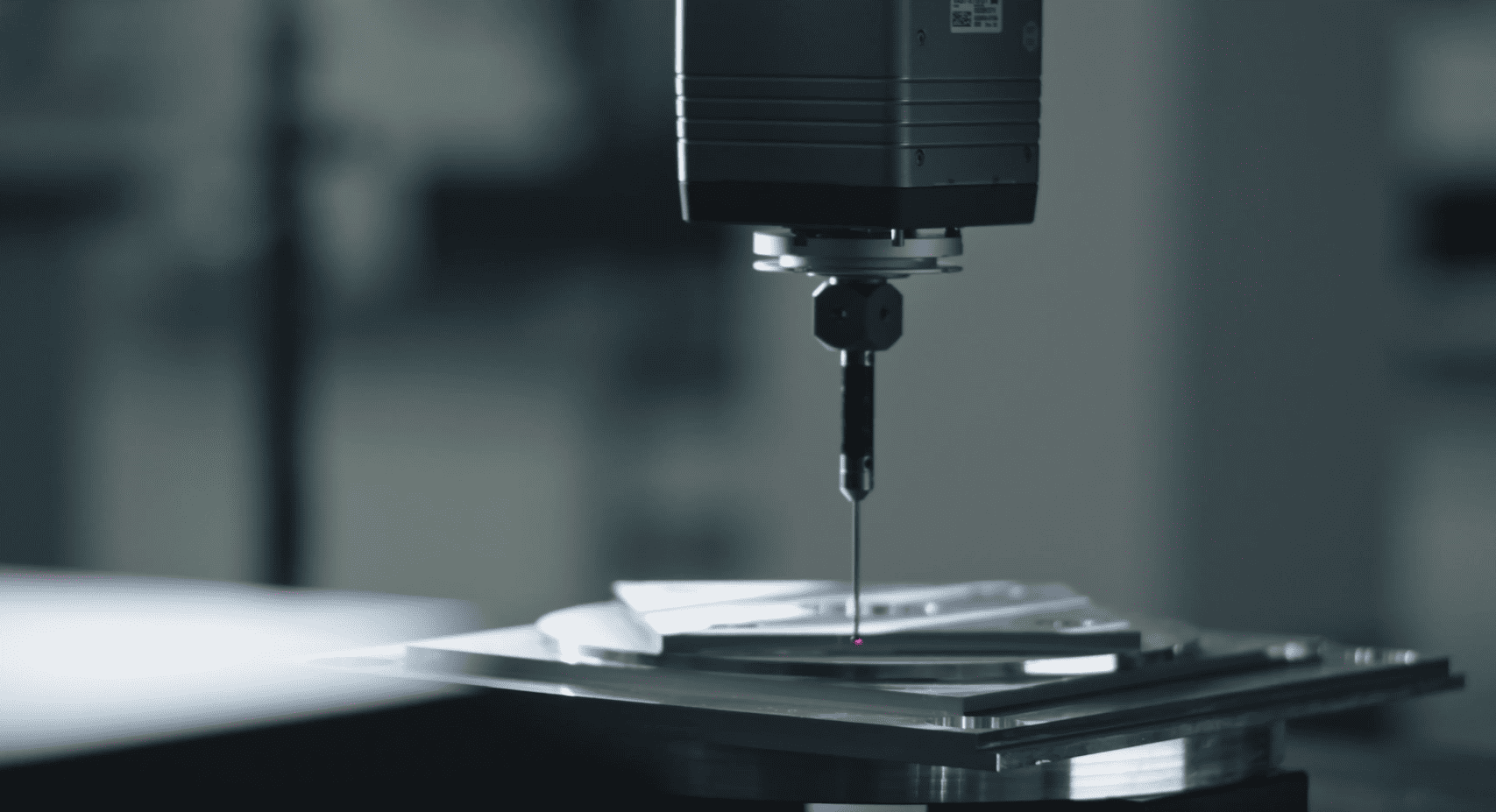

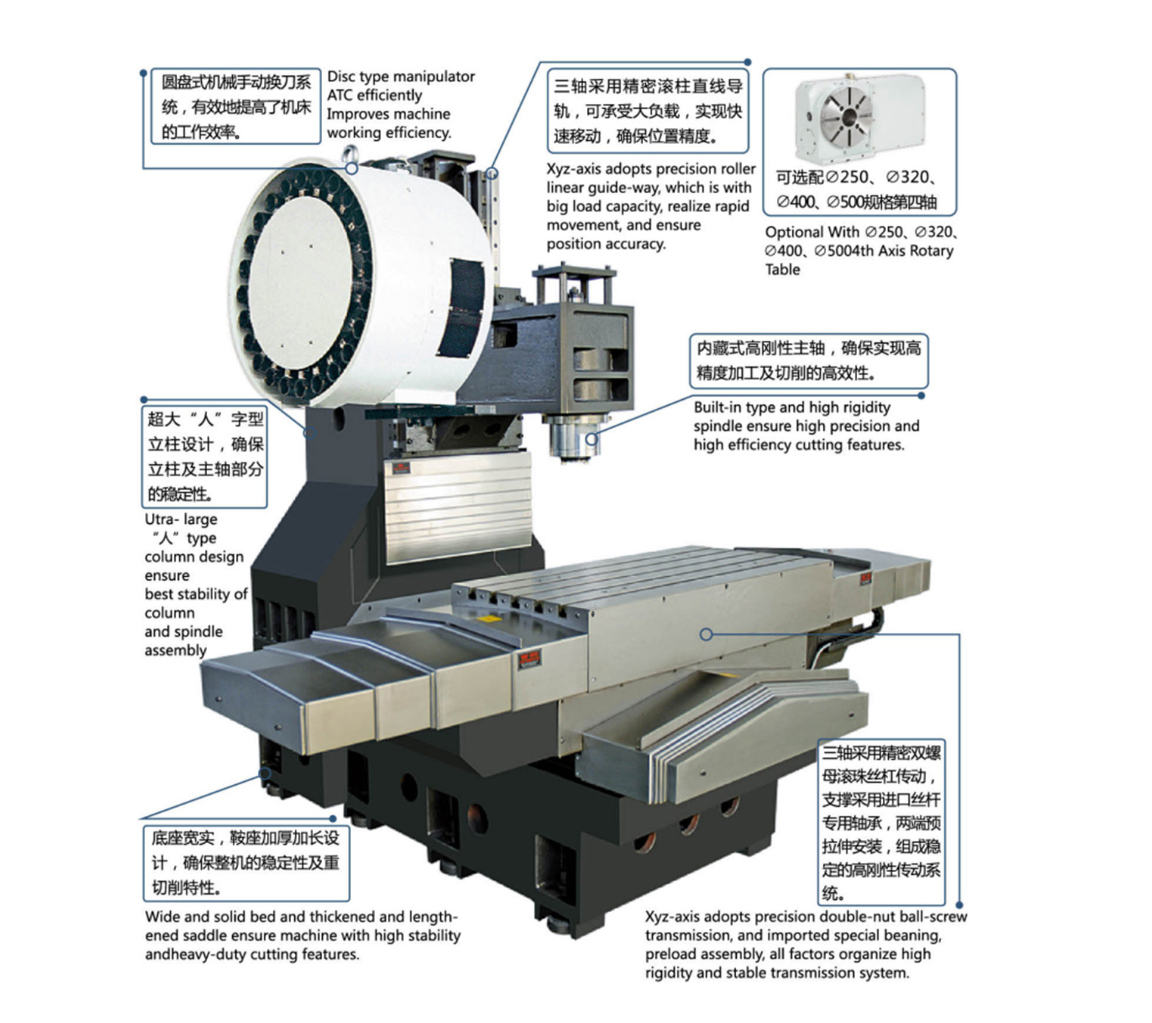

·Vertical machining centers

The most common type is the vertical machining center. Its spindle is perpendicular to the worktable and is most suitable for machining workpieces with relatively small height dimensions. The vertical machining center generally has three linear motion coordinates. If indexing and rotation functions are required, a CNC turntable with a horizontal axis can be installed on the worktable to process parts with spiral grooves and other parts that require four-axis linkage processing.

The vertical machining center can be used to process simple boxes, box covers, plates, flat cams and other parts. It can complete production processes such as milling, boring, drilling, tapping and cutting threads. It has the advantages of simple structure, small footprint and low price.

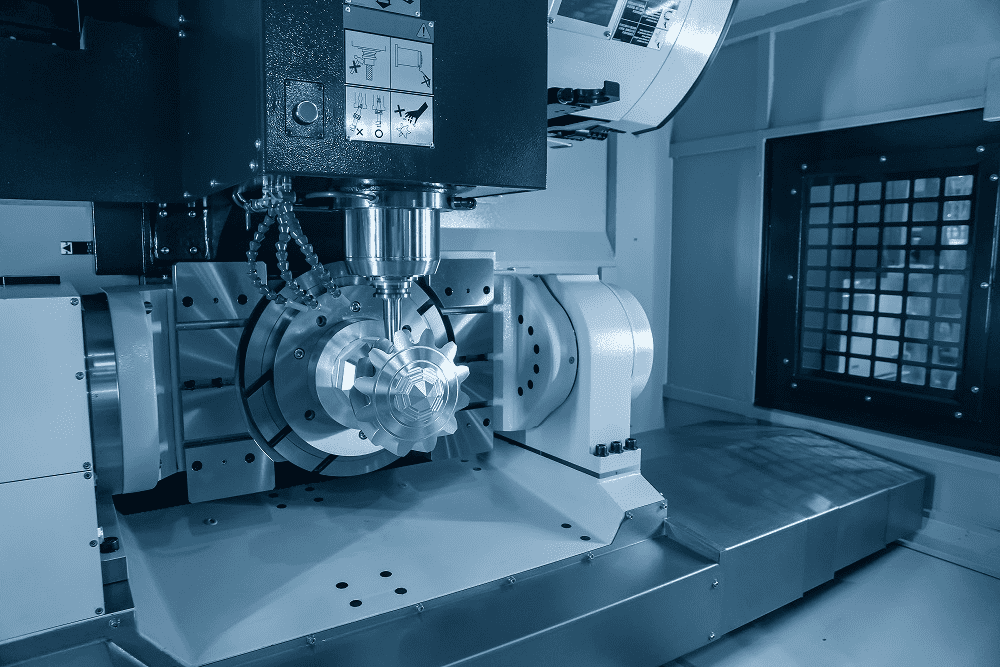

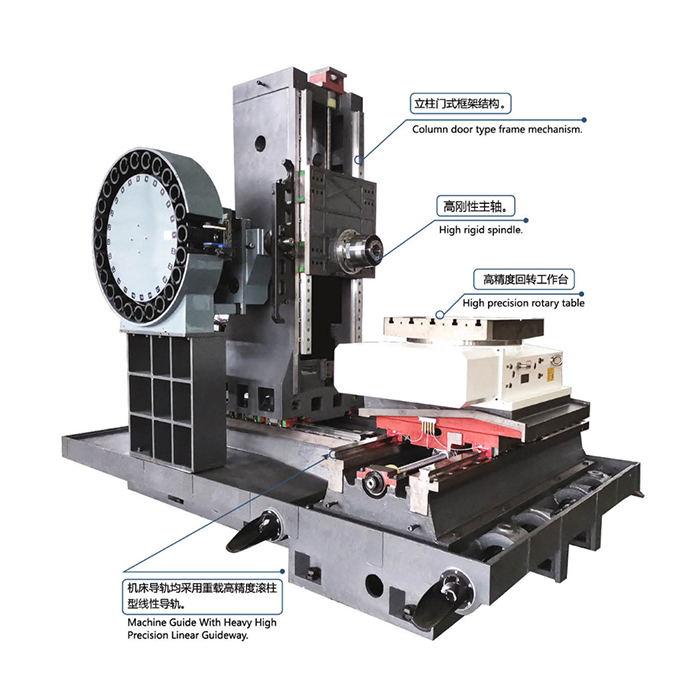

·Horizontal machining centers

The spindle of the horizontal machining center is parallel to the worktable. Due to the characteristics of its structure and layout, it is most suitable for processing box-type parts. Horizontal machining centers generally have 3 to 5 motion coordinates. Commonly used are three linear motion coordinates (along the X, Y, and Z axes) plus a rotary coordinate (worktable), which enables the workpiece to complete the processing of the remaining four surfaces except the mounting surface and the top surface in one clamping.

The horizontal machining center has a wider range of applications than the vertical machining center. It is suitable for multi-process processing such as milling, drilling, boring, reaming, tapping, two-dimensional and three-dimensional curved surfaces of multiple working surfaces of parts. It has good performance in completing the box body hole system and plane processing in one clamping. It is suitable for the processing of complex box parts, pump bodies, valve bodies and other parts. It is widely used in industries such as automobiles, internal combustion engines, aerospace, home appliances, and general machinery. However, the horizontal machining center occupies a large area and is heavy; the structure is complex and the price is relatively high.

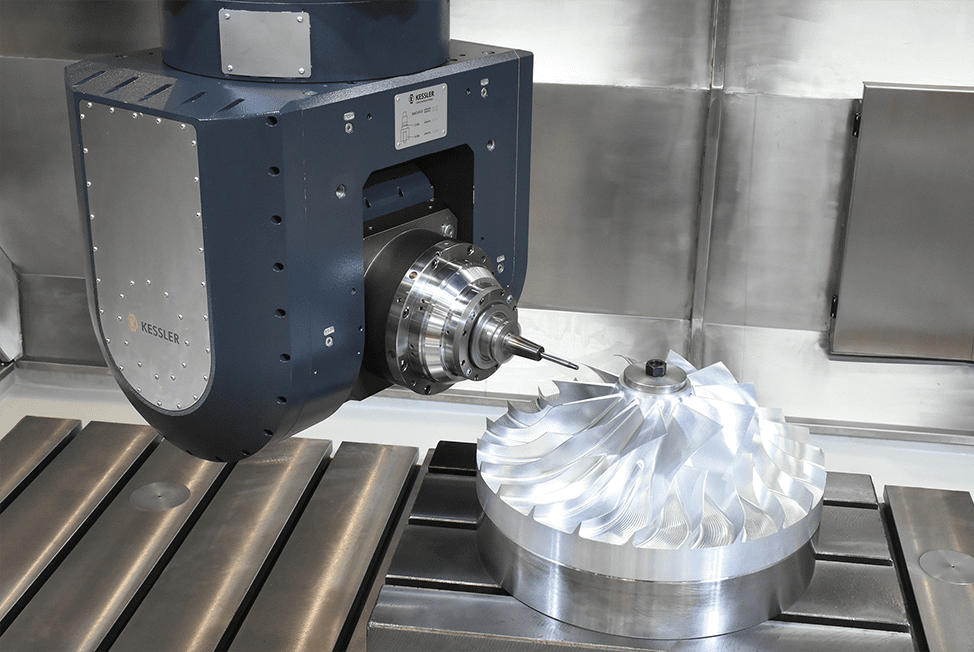

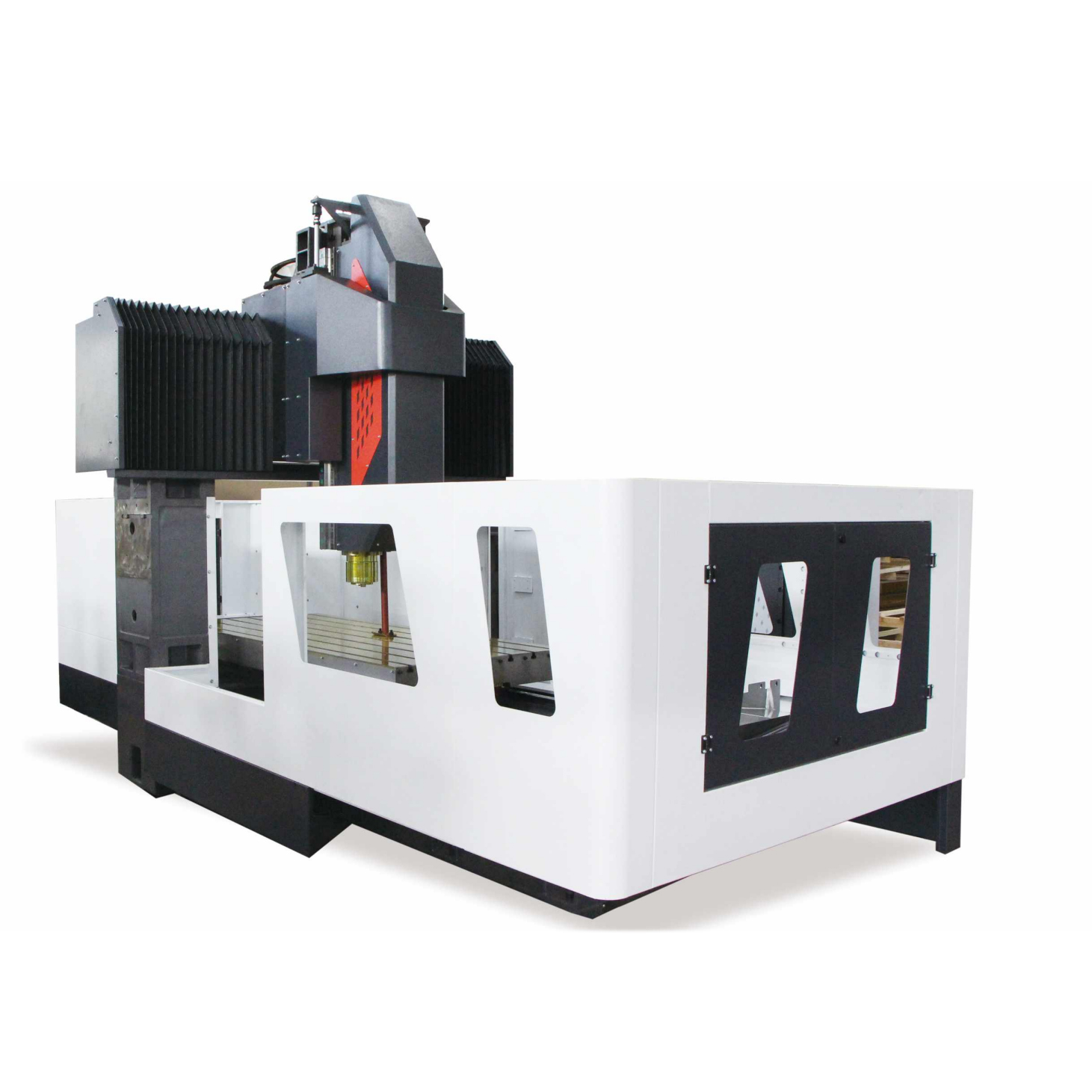

·Gantry machining centers

The gantry machining center is similar to the gantry milling machine. It refers to a machining center where the axis of the spindle Z axis is set perpendicular to the worktable. The overall structure is a large-scale machining center machine with a gantry structure frame composed of double columns and top beams, and there is a crossbeam in the middle of the double columns. The movement of the three coordinate axes of X, Y, and Z is used to achieve multi-directional processing, and the processing of the five surfaces of the workpiece is completed.

The gantry machining center can automatically perform multi-process processing such as milling, boring, drilling, and tapping to meet various processing needs: drilling, tapping, milling, boring, chamfering, etc. The gantry machining center has important applications in aerospace, mold manufacturing, and rail transportation. It is especially suitable for processing large workpieces and workpieces with complex shapes.

Classification of gantry machining centers:

·fixed beam type (fixed beam, movable/rotating worktable),

·movable beam type (beam moves up and down, worktable moves forward and backward),

·movable column type (worktable is fixed, gantry moves),

·overhead crane type (worktable is fixed, beam moves)

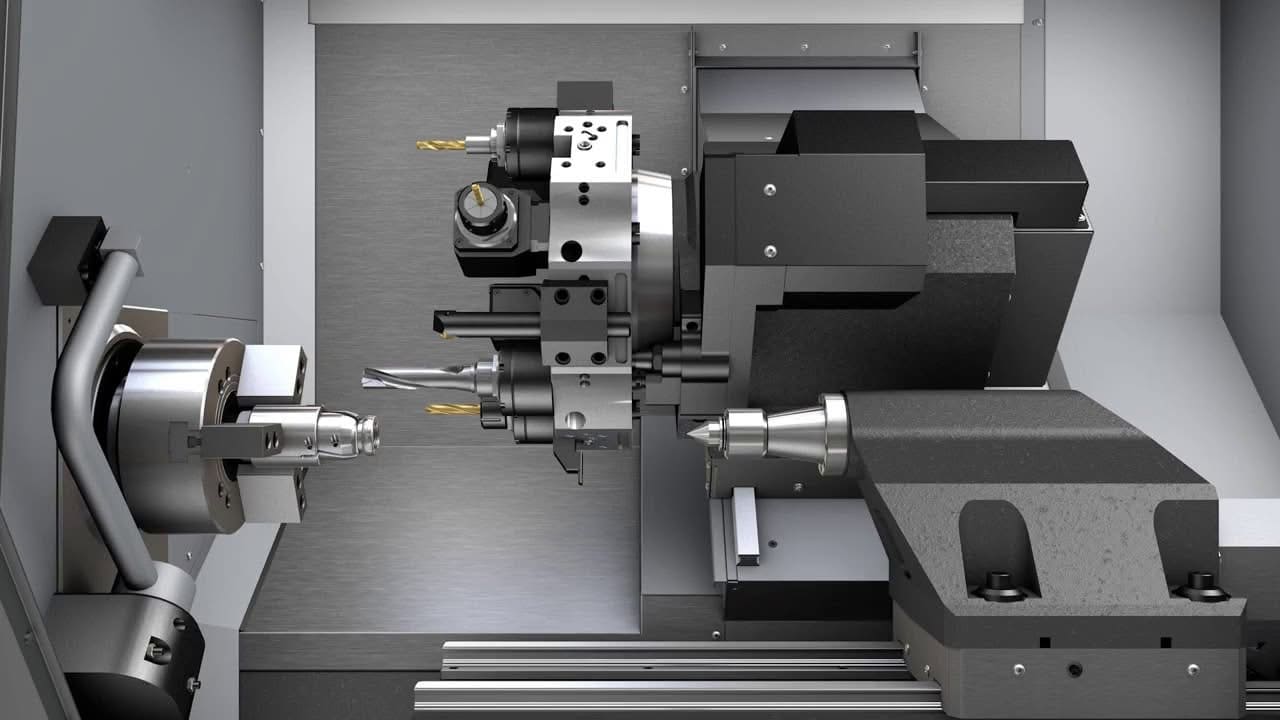

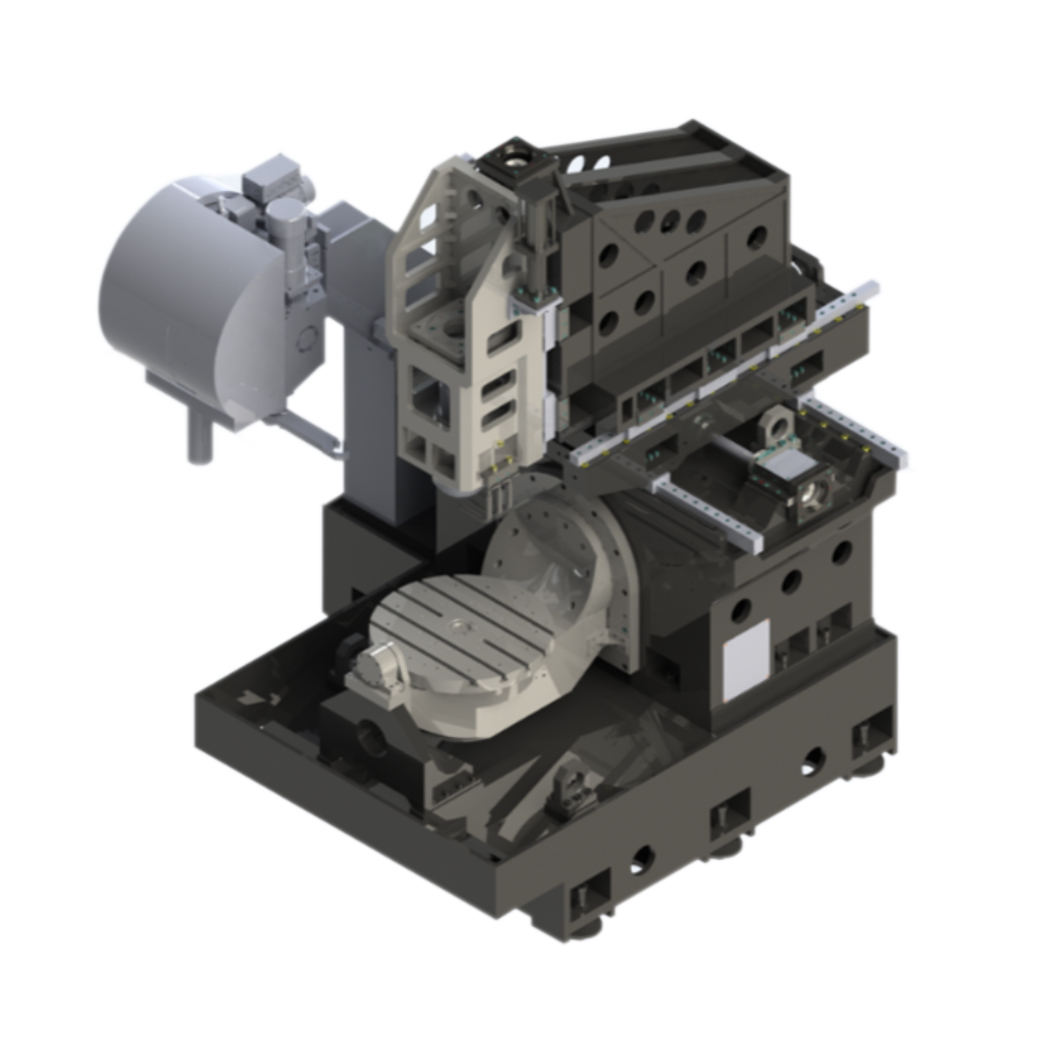

Compound machining centers

The compound machining center, also known as the five-face machining center, combines the characteristics of several layout structures such as vertical, horizontal and gantry, and is suitable for processing many different types of parts. The general workpiece clamping can complete the processing of all surfaces except the installation surface, and has the functions of vertical and horizontal machining centers.

There are two common types of compound machining centers: one is that the spindle can rotate 90°, which can be like a vertical machining center or a horizontal machining center; the other is that the spindle does not change direction, and the worktable rotates 90° with the workpiece to complete the processing of the five surfaces of the workpiece. Installing the workpiece on the compound machining center avoids the installation error caused by secondary clamping, so the efficiency and precision are high, but the structure is complex and the cost is also high. Due to the disadvantages of complex structure, high cost and large floor space of the compound machining center, its use and production are far less than other types of machining centers.

According to the characteristics, capabilities and product processing purposes of the processing, they are not exactly the same.

2.Classification by the number of motion coordinates :

Machining centers can be divided into: three-axis two-linkage, three-axis three-linkage, four-axis three-linkage, four-axis four-linkage, five-axis four-linkage, five-axis five-linkage, six-axis five-linkage, etc.

The number of axes refers to the number of motion coordinates of the machining center, and linkage refers to the number of motion coordinates that the control system can control at the same time to achieve the position and speed control of the tool relative to the workpiece.

3.Classification by number of workbenches

·single-table machining centers

·double-table machining centers

·multi-table machining centers

4.Classification by processing technology

·milling machining centers

·drilling machining centers

·combined machining centers

Milling machining centers are mainly used for plane milling, contour milling and surface milling, and are widely used in automotive parts, shipbuilding, aerospace and other fields.

Drilling machining centers are mainly used for hole processing, such as bearing holes, oil holes and cooling water holes.

Combined machining centers integrate multiple functions such as milling machines, drilling machines and tapping machines, and are suitable for the processing of complex parts.

5.Classification by number of spindles

The number of spindles in a machining center can be divided into single-spindle machining centers and dual-spindle machining centers. A single-spindle machining center has only one spindle, which is suitable for single-piece and small-batch production. A dual-spindle machining center has two spindles, which can process two parts at the same time, improving production efficiency.

There are many ways to classify machining centers. Different classification standards can give us a more comprehensive understanding of the characteristics and applications of machining centers. Machining centers are indispensable and important equipment in modern manufacturing. Through the introduction of the classification and application fields of different types of machining centers, I hope that everyone can better understand and choose a machining center that suits their needs. Thereby improving efficiency in production, improving product quality, and achieving greater economic benefits.

How to choose a high-quality machining center? Shandong Youka CNC Machinery Co., Ltd., as a new generation of manufacturers, has a professional team of engineers, a production technology team, and a high-quality accessories supply chain. It can provide you with detailed solutions to help companies quickly choose suitable machines and save procurement costs, save procurement time, and improve procurement efficiency. Providing high-precision, high-quality, and cost-effective machines to a large number of global users is the value of YOUKA-CNC.