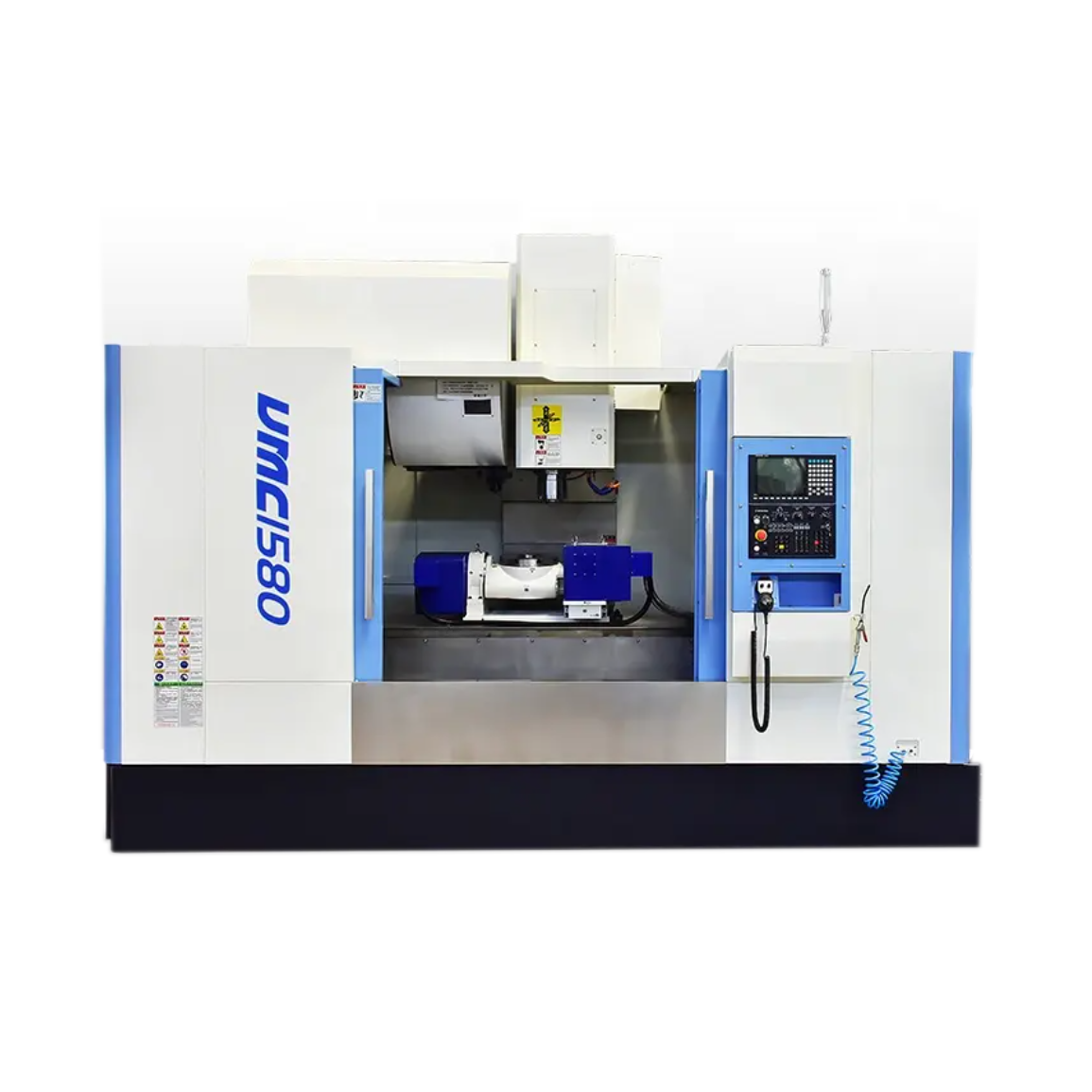

Vertical CNC Turning Machining Center VMC1270 Feature

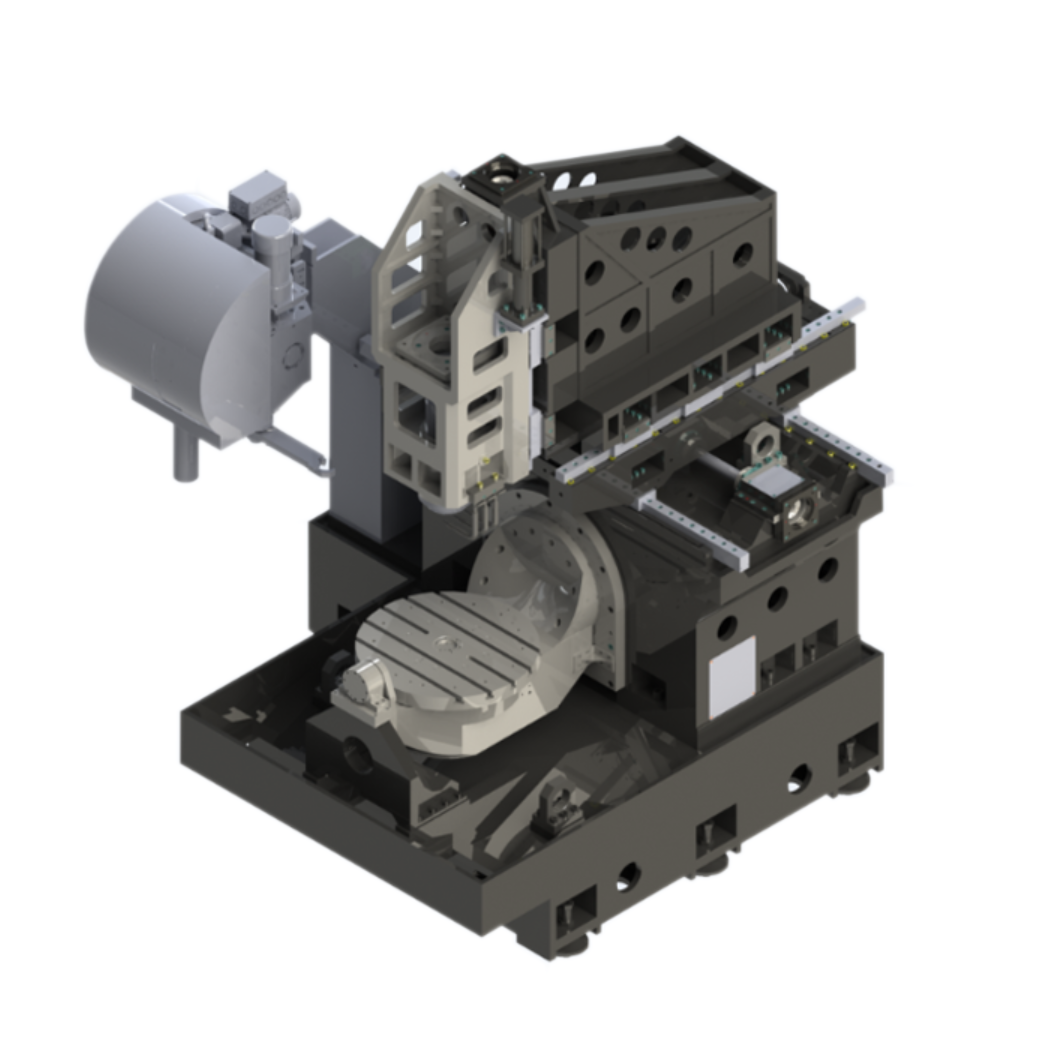

· Three axes use linear guide rails, which have high rigidity, high positioning accuracy, low noise, and low friction. They can achieve fast displacement and the best circular accuracy.

· The castings are analyzed by computer calculation using the finite element analysis method, and the reasonable structural strength and reinforcement ribs are matched to provide high rigidity of the machine.

· Vetical CNC Turning Machining Center Main technical parameters:

|

Model |

VMC1270 |

|

|

Travel |

X axis |

1200mm |

| Y axis |

700mm |

|

| Z axis |

650mm |

|

| Spindle nose to table |

130-780mm |

|

| Max. X,Y ,Z rapid feed |

16m/min |

|

|

Table |

Table size |

1360x700mm |

| Max. load |

1000kg |

|

| T slot |

18-5-122mm |

|

|

Spindle |

Type |

Belt |

| Speed |

8000rpm |

|

| Spindle diameter |

155mm |

|

| Spindle taper |

BT50 |

|

| Main motor |

15kw |

|

|

Acuracy |

Positioning Accuracy |

±0.005mm |

| Repeatibility |

±0.003mm |

|

|

Machine |

Size |

3600x2500x2700mm |

| Weight |

9300kg |

|